Safeguard Your Car From The Elements With A New Heat Shield

We all know that the innovative technology aimed at improving our cars is advancing incredibly fast these days. And, like most other industry insiders, we are sure you have noticed how exhaust pipes are no exception to this rule. Many of these piping systems come with an additional heat shield wrapped around the pipe. But what does this wrap do, and why can’t drivers just aim to “nix” it? Without getting too techie, there are many reasons why exhaust system heat shields are important – both to your engine and for your safety on the road.

Is it really necessary to get a heat shield for any of your cars?

As perhaps the final line of defence to protect your car from harm, heat shield for car should be top priority. Sometimes exhaust pipes get damaged from other vehicles, errant road debris, or from rusting. But whatever caused the damage, there’s a pretty good chance it started with them lacking a heat shield in the first place. The same can be said for a car that’s missing a lot of its original parts.

This metal guard keeps the exhaust system on your car from getting too hot. Heat can be dangerous for internal components on your car or van insulation in Australia , and it also helps prevent the paint from peeling off behind the exhaust if the pipe begins to rust.

So yes, a heat shield works in keeping you and your car safe. And is it worth the money?

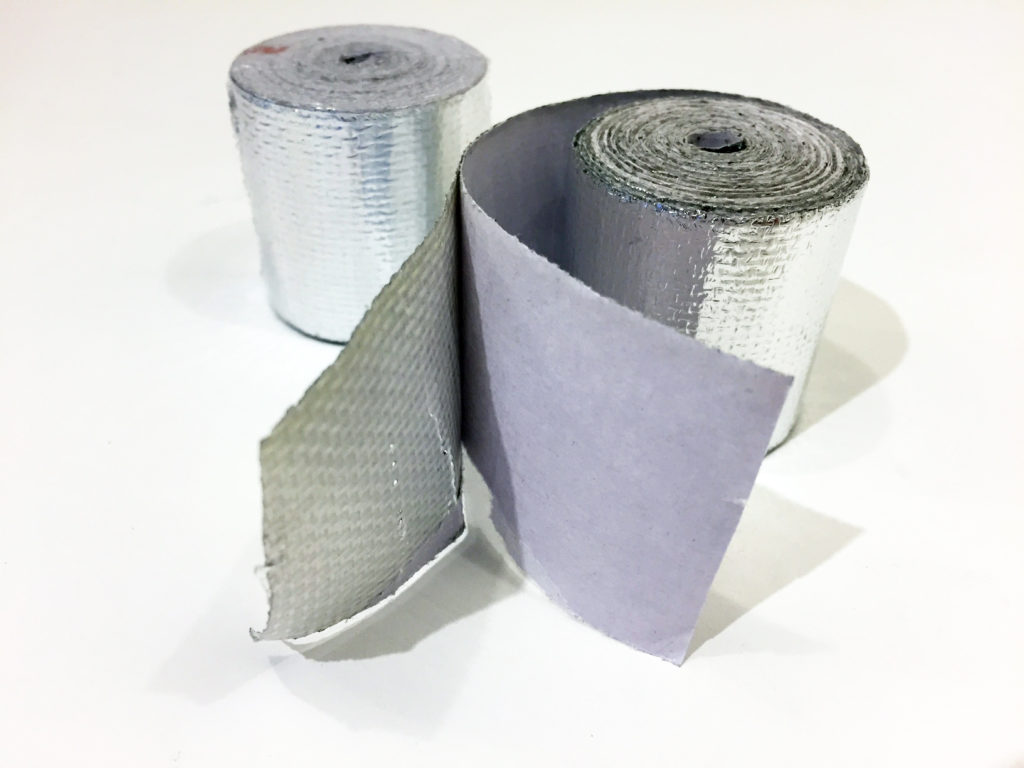

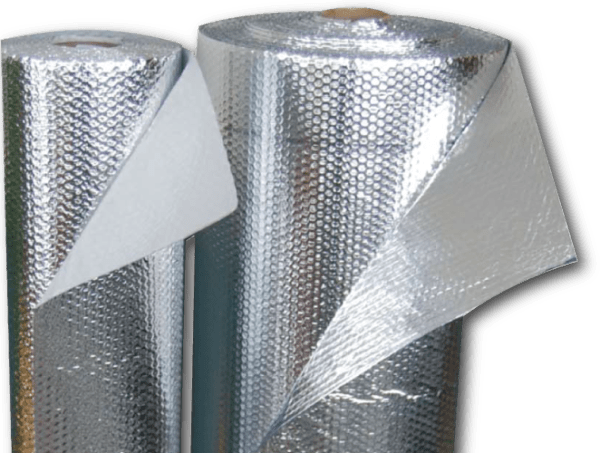

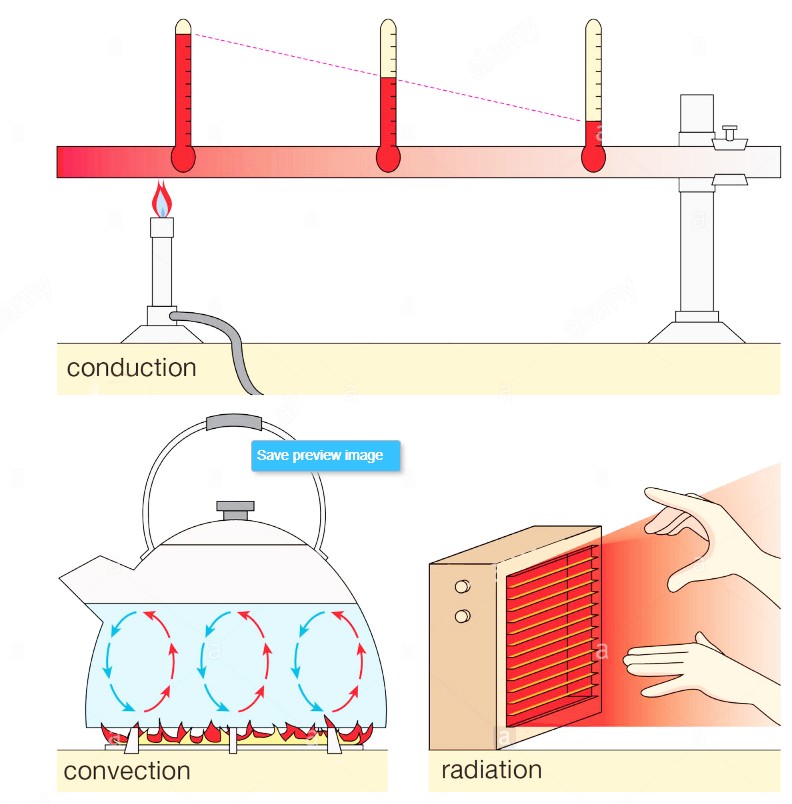

Exhaust wrap is used to reduce heat-related paint damage, not necessarily increase performance or fuel economy. It can be used on any surface of the vehicle but usually wraps the exhaust system. The heat shield/wrap does not “insulate” your vehicle–it simply converts the radiant heat into reflective infrared energy (longer wavelength) that is less likely to cause damage, which is why it can be placed anywhere on your car.

Automotive Heat shield to increase the life of Vehicle engine

There are two main types of automotive heat shields: external and internal. The external heat shield is built from a heavy-duty metal or stainless steel and is placed around a specific component. The internal heat shield is a thin sheet of metal that has been wound for lightweight and install ease. Heat shields can be an excellent way to help your engine last longer by providing additional protection against the high temperatures caused by heat build-up. The lifetime of your engine and the quality of your ride can be improved with an automotive heat shield car installation. This car modification may seem like a small thing, but it is very important for motorists who want to avoid losing their engine power, as well as those who want their cars to perform at their best level.