Addressing Common Misconceptions About Exhaust Wrap

Exhaust wrap is widely discussed in the automotive world, often surrounded by various myths and misconceptions. As a leading heat shield and exhaust wrap solutions provider, Kool Wrap is here to set the record straight. This blog post addresses and debunks some of the most common misconceptions about exhaust wrap, clarifying its benefits and dispelling misinformation.

Misconception 1: Exhaust Wrap is Only for Aesthetics

One common misconception is that exhaust wrap is solely used for cosmetic purposes, giving vehicles a “cool” look. While it’s true that a well-wrapped exhaust can have an appealing appearance, its benefits go far beyond aesthetics. Exhaust wrap is primarily employed to manage heat. It helps reduce under-hood temperatures, protect nearby components, and improve overall engine performance.

Misconception 2: Exhaust Wrap Causes Corrosion

Some believe wrapping the exhaust can trap moisture and lead to rust or corrosion. However, modern exhaust wrap materials are designed to resist moisture and heat. When correctly installed, they create a barrier that minimises the chance of moisture accumulation, preventing corrosion rather than causing it.

Misconception 3: Exhaust Wrap Decreases Exhaust Life

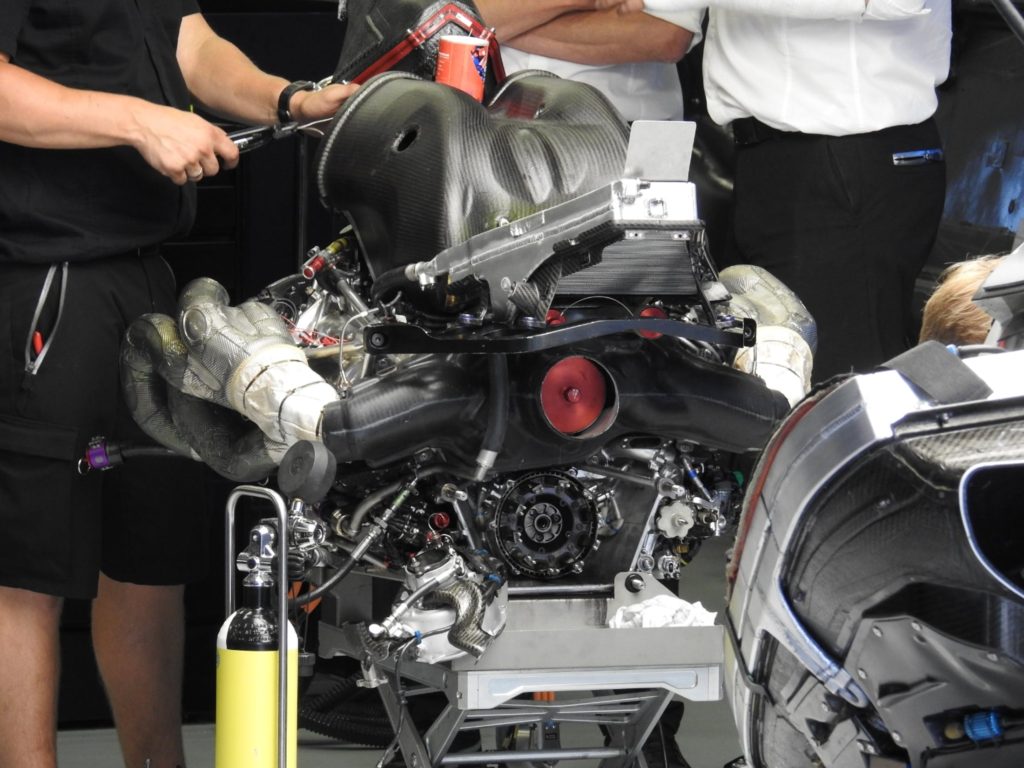

There’s a notion that exhaust wrap can accelerate wear and tear on the exhaust system due to increased heat retention. In reality, well-engineered exhaust wrap materials are designed to withstand high temperatures. They are often used in racing and high-performance applications precisely to prolong the life of the exhaust by reducing thermal stress.

Misconception 4: Exhaust Wrap Always Leads to Performance Gains

While exhaust wrap can improve performance by reducing heat soak and enhancing exhaust gas flow, it’s not a magic solution that guarantees horsepower gains on every vehicle. The extent of performance improvement can vary based on factors such as the engine’s design, the wrap’s quality, and the vehicle’s overall setup.

Misconception 5: Exhaust Wrap Is Only for Racing Vehicles

Another misconception is that exhaust wrap is exclusive to racing vehicles. While it’s true that race cars often utilise exhaust wrap for performance reasons, it’s equally valuable for regular daily drivers. Exhaust wrap can help prevent heat-related damage, increase fuel efficiency, and even reduce cabin heat, making it beneficial for all types of vehicles.

Benefits of Exhaust Wrap

Heat Management: Exhaust wrap effectively reduces under-hood temperatures, leading to improved engine performance, reduced heat-related issues, and enhanced overall reliability.

Protection: By shielding nearby components from excessive heat, exhaust wrap prevents potential damage and extends the life of various parts.

Performance Enhancement: While not a guaranteed horsepower boost, exhaust wrap can improve exhaust gas flow, contributing to a smoother-running engine.

Fuel Efficiency: Cooler air entering the engine bay can improve fuel combustion efficiency, potentially leading to better fuel mileage.

Cabin Comfort: Lower under-hood temperatures translate to cooler cabin interiors, making your driving experience more comfortable.

Conclusion

Exhaust wrap is a practical and beneficial solution that extends beyond aesthetics. It manages heat, protects components, and enhances vehicle performance. By addressing and debunking common misconceptions, we hope to clarify the advantages of using exhaust wrap. At Kool Wrap, we offer high-quality heat shield and exhaust wrap products to help you make informed decisions for your vehicle’s well-being and performance.