Keeping Fire Under Wraps

In 2013, the NSW government released a report analysing all underground metalliferous mine fire incidents from 2008-2012. During this period 128 fires were reported at underground metalliferous mines for an average of 26 underground fires per year, of which mobile plant accounted for 76% of those fires. The report goes on to mention that 20% of all reportable incidents were fire related, and that fire comprised approximately 25% of all reportable incidents regarding mechanical plant. Of these, 18% were reported as resulting in damage to plant. Thankfully, there was only one fire-related injury during this period.

The report also highlighted that the most common heat sources for fires are the exhaust system, engine surfaces and turbochargers, while the most common fuel source is hydraulic oil, lubricating oil, fuel and grease. This reflects a common scenario in mining whereby a combustible oil leaks from a hose or fitting onto or near a hot surface in the engine compartment causing it to ignite.

The report goes on to make several recommendations, specifically that ‘consideration should be given to the consequences of oil and fuel coming into contact with hot engine components as part of a fire risk assessment. Where reasonably practicable consider shielding to prevent that contact.’

Kool Wrap is a company with a range of products that helps equipment owners adhere to the recommendation made above. Their products are designed to significantly reduce the incidence of mechanical equipment fires by providing a physical, fire-resistant barrier between the combustible fluids and the hot surfaces by mitigating against various types of heat transfer including convection (where heat is carried by a liquid from one part to another), conduction (where heat is transferred through the object itself), and radiation (where heat is emitted as through the air).

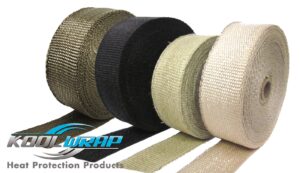

Kool Wrap’s products are made from various types of heat-resistant materials including heat-treated fibreglass as well as new materials such as basalt fibres (known as ‘lava wrap’), which comes with a higher heat rating than fibreglass and has various applications such as inside turbo blankets, heat sleeves, and reflective wrapping.

What makes Kool Wrap cool?

The products are hand-tailored and are offered as off-the-shelf items for many common applications or can be customised to suit any application. The typical composition begins with a stainless steel mesh, followed by a 10-20mm thick section of silicon or needle-felt wool (which provides air pockets responsible for the insulation) held in place by a fibreglass outer layer. The fibreglass layer is then coated in Silicon or Teflon (which prevents oil or fuel soaking into the fibreglass) and then it is finally stitched together with Kevlar or Fibreglass thread, resulting in a durable, reliable and safe product.

Turbo Blanket Advantages

During the combustion phase of an engine cycle, rapidly expanding exhaust gas is pushed out of the combustion chamber by the upward movement of the piston. The hotter the gas, the faster it expands. Likewise, if it is allowed to cool (i.e. dissipate heat) then the expansion slows. It is the rapid expansion of gas that turns the compressor wheel in a turbocharger. The faster the gas expands, the faster the turbo spins.

Normally, heat is dissipated into the turbo exhaust housing and then transferred into the air in the engine compartment, which provides an element of cooling. However, a turbocharger housing operating under load can exceed 1000°C, which is enough to instantly heat most flammable liquids to flash point, creating an engine bay fire.

By installing a turbo blanket, not only does the insulating properties of the blanket protect other components in the engine bay from the heat emitted by the turbo but it actually improves the performance of the turbo by ensuring the gas inside the turbo remains hot for as long as possible. By wrapping the turbo in a Kool Wrap exhaust blanket, the heat is kept inside the compressor housing where it belongs, improving the overall performance.

From a safety perspective, the turbo blanket can prevent serious burns and keep maintenance personnel from contacting these dangerously hot surfaces.

Heat Trick Up Their Sleeve.

The residual heat emitted from engines, turbos, exhaust manifolds and exhaust pipes can cause damage to pipes and hoses not designed to withstand high temperatures – for example flexible hydraulic and fuel lines. By wrapping these lines in Kool Wrap heat sleeves, they are insulated from any conduction or convection within the engine compartment. Since the heat sleeves are often lined in reflecting aluminium foil (which can handle up to 600°C), radiant heat is also deflected. Protecting flexible lines in this way not only prevents them from melting and releasing fluid onto hot surfaces but it also delays the rate at which they degrade, for longer service life.

About Kool Wrap

Kool Wrap has been a successful Australian supplier of heat protection products since 1995, originally providing heat sleeves and exhaust lagging to the high-performance car racing industry and then later moving into heavy industries such as the marine sector, farming and mining. Their product range not only includes turbo blankets and heat sleeves but other products such as embossed aluminium heat shield panels, heat reflective tape and other forms of heat protection available on their website.

Fire is one of the greatest hazards in the mining industry, causing substantial damage to plant and equipment, creating significant costs to operators and potentially life-threatening risks to personnel.

It is for this reason that appropriate, fit for purpose heat protection devices must be fitted to not only comply with statutory regulations but also to avert the hazards of onsite fire.

Source

Kool Wrap