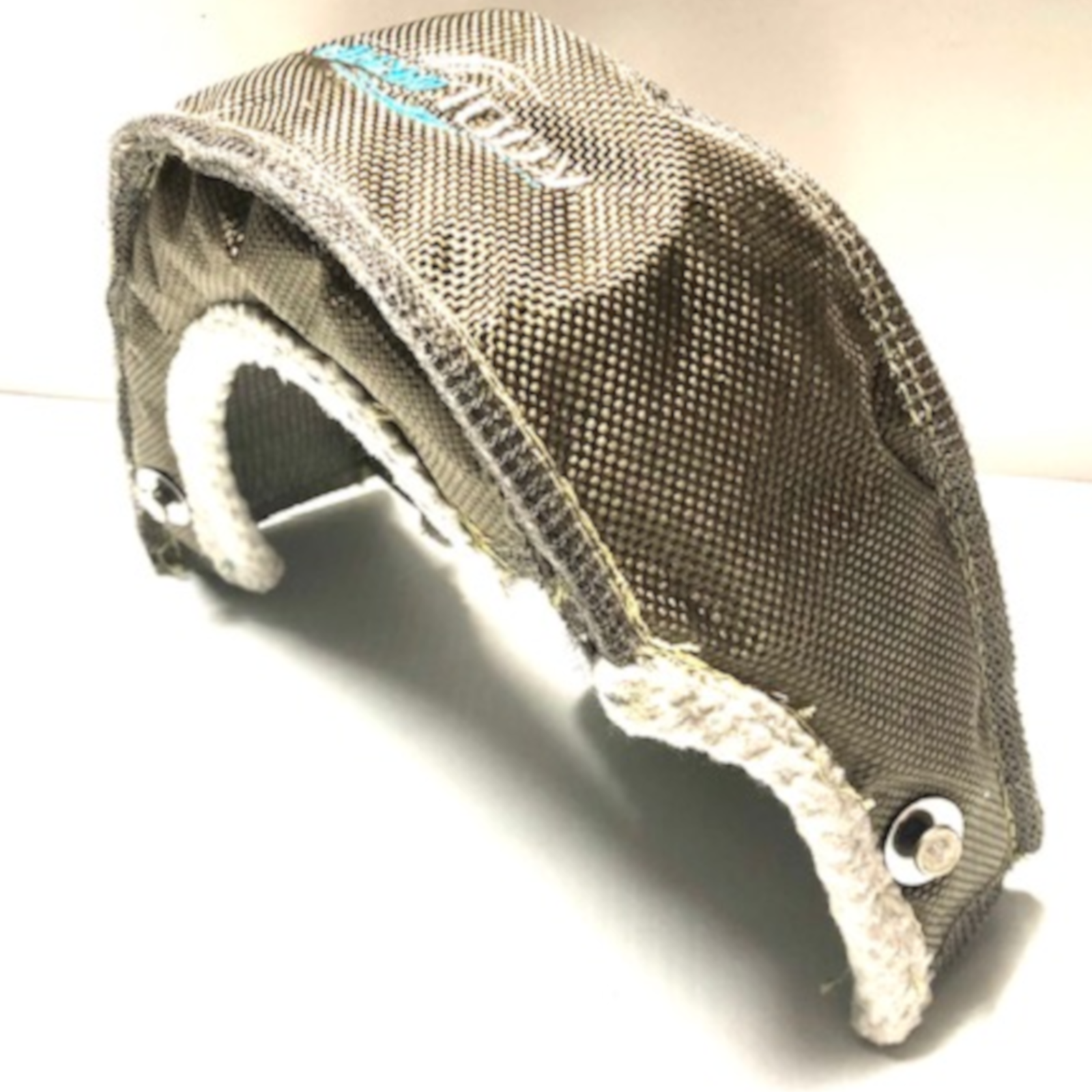

Titanium Basalt Turbo Blankets

-

Kool Wrap Titanium Turbo Blanket, T3

95.50 Add to cart -

Kool Wrap Titanium Basalt Turbo Blanket/ Beanie, T4 size

105.50 Add to cart -

Kool Wrap Titanium Turbo Blanket, T6

115.50 Add to cart -

Kool Wrap Titanium Turbo Blanket, T2

85.50 Add to cart -

Kool Wrap WRX Turbo Blanket 2.0L / 2.5L EJ20 / EJ25 H4 Turbocharged Engine

99.50 Add to cart -

Kool Wrap Titanium Turbo Blanket, T3 size with Internal Wastegate T25, T28

139.50 Add to cart -

Kool Wrap Titanium Turbo Blanket, T2 size with Internal Wastegate

124.50 Add to cart -

TURBOMOTIV STOCK FRAME TITANIUM BASALT TURBO BLANKET MITSUBISHI EVO X

450.00 Add to cart -

Kool Wrap Titanium Turbo Blanket, VW, Audi 2006-2014 K-04

139.50 Add to cart -

Kool Wrap Titanium Turbo Blanket, Toyota Land Cruiser 4.2L 1HDT Diesel engine

375.00 Add to cart -

Kool Wrap Turbo Blanket CAT C13 C15 and Similar Turbos with built in wastegates

119.50 Add to cart -

Kool Wrap Turbo Blanket for GT25-GT28,

215.50 Add to cart

The Kool Wrap Titanium Basalt Turbo Blanket is designed for the highest temperature Turbochargers and has a heat rating of over 1,000°C. It features 12mm thick internal silica insulation and a Titanium Basalt woven outer cover. External Kevlar stitching keeps the stitched seam away from the hot turbo housing. Ideal for all applications but especially high horsepower engines. Available in a wide range of sizes.