The best heat shield protection for performance cars

Heat shield products to help your car keep its cool

Can your car handle the heat? It’s a question that any revhead should ask themselves when it comes to their performance car. Heat management is one of the most important aspects of automotive design. So if you’ve modified your car for performance, you better hope everything is set up to handle that extra heat.

Components of your car like the engine, gearbox, and brakes rely on heat to work as intended. But if you apply too much heat to these components then it could result in a loss of performance or permanent damage. When high temperatures are generated in your car, it can also cause a significant amount of power loss.

If this is all news to you, then it’s time to listen up. The performance and safety of your car are at stake. The temperature of your car can be lowered to a safe range with the right accessories and gear. Thermal management products like heat shield tape are perfect for solving your performance car’s overheating issues. If you’d like to learn more, then read on to see our recommendations for heat shield tape and other heat shield protection products.

Car parts that need heat protection

To properly manage heat in your car, it’s important to narrow down the problem areas. Find out which areas produce the most heat while running and you can focus on the components that need the most heat protection. Make the following components your top priority:

Exhaust

Located under the engine bay, the exhaust helps to dissipate heat from the engine. It’s the extreme heat travelling along the pipe of the exhaust you need to worry about. Applying heat shield tape or exhaust wrap to the exhaust pipe can help to protect engine components, wiring or hoses in or under your engine bay from excess heat. This can also help make your exhaust more efficient.

Our recommendation:

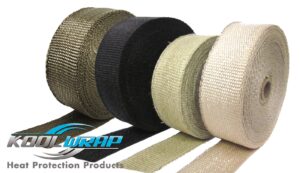

Kool Wrap Vermiculite Exhaust Wrap

This vermiculite treated exhaust tape is highly flexible and easy to wrap around your exhaust. Made from a specially trated fibreglass, this wrap is naturally resistant to heat with a melting point of 1093 degrees celsius. When applied correctly, this exhaust wrap can help reduce under-bonnet heat by as much as 50% to provide a cooler intake charge.

Bonnet

Under the bonnet of your car is where a vast majority of heat is produced. This heat production is caused by the placement of the engine. Turbo and supercharged cars are particularly susceptible to high engine bay heat. Engine bay temperatures can reach super hot levels that increase the risk of damaging the paintwork of your car’s bonnet.

Our recommendation:

Kool Wrap Adhesive Heat Shield

Our adhesive heat shield is perfect for under bonnet insulation. It’s made with an outer layer of reflective aluminium foil, insulating foam, fibreglass backing, and a pressure-sensitive heat resistant adhesive layer. Installing this heat shield can help block radiant heat from damaging your bonnet.

Turbocharger

A turbocharger is responsible for increasing your car engine’s efficiency and power. It achieves this by forcing additional compressed air into the combustion chamber of the engine. With this performance upgrade comes additional and immense heat production. Components situated around the turbocharger are all at risk of excess heat damage if they’re not shielded correctly.

Our recommendation:

Kool Wrap Titanium Turbo Blanket

A turbo blanket can effectively prevent and isolate heat from your car’s turbocharger. These blankets can also help protect surrounding components such as plastic hoses and electrical wires. Our very own Kool Wrap Titanium turbo blanket is specially designed to reduce radiant heat coming from the turbocharger.

The outer layer of our turbo blanket boasts one of the highest heat ratings of any known material. The inner liner is made from high-temperature resistant silica insulation held in place with a stainless steel mesh and sewn together with kevlar stitching.

Ask the experts at Kool Wrap

Looking to turbocharge the performance of your car? You’ll need to install the right heat shield protection to keep your car cool during peak performance. If you’re looking for more expert advice on car cooling, speak to the experts at Kool Wrap. As a leading supplier of Australian made cooling products, the team at Kool wrap can offer valuable advice to help you choose the right cooling products.

Ask the experts at Kool Wrap for advice on professional heat protection products.